| DISSOLUTION EFFICIENCY | UP TO 50%

• Performance is more closely linked to the water column and the resulting bubble retention time, rather than to installed power.

• Technical gases like ozone and oxygen can be injected in its standard configuration as well. This feature makes it the perfect solution whenever a strong chemical oxidation is required. | UP TO 7%

• Its performance can be increased using add-on components (circulators)

• They can only inject air.

• As the water column increases, the power required for operation will increase accordingly. | UP TO 25/30%

The installed power is directly linked to the depth of the tank and to the resulting pressure that the pump has to overcome. It can only inject air. |

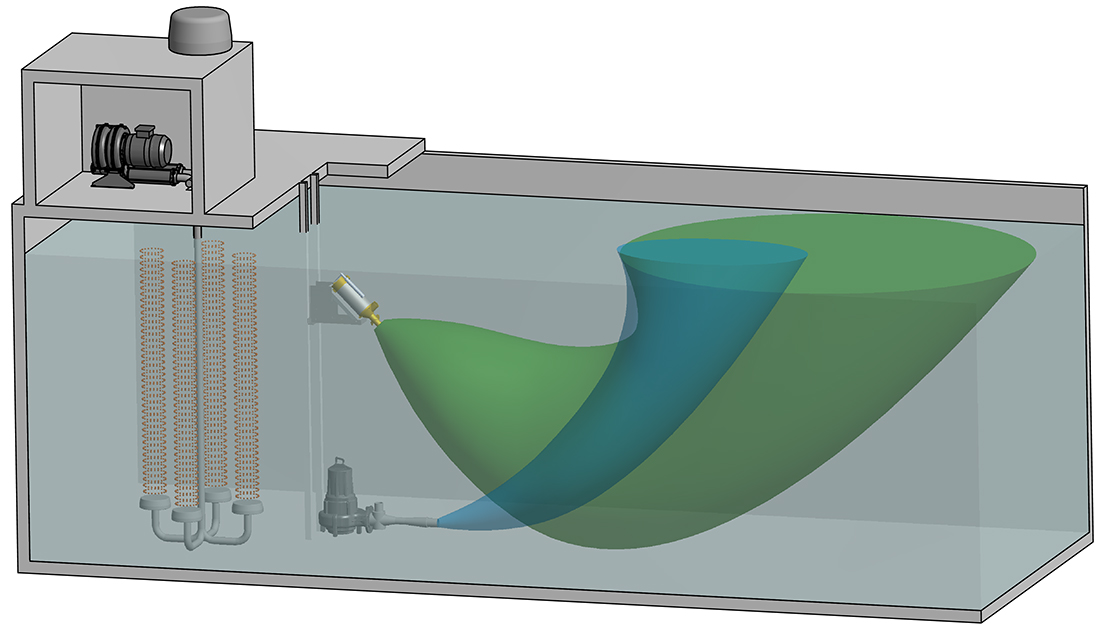

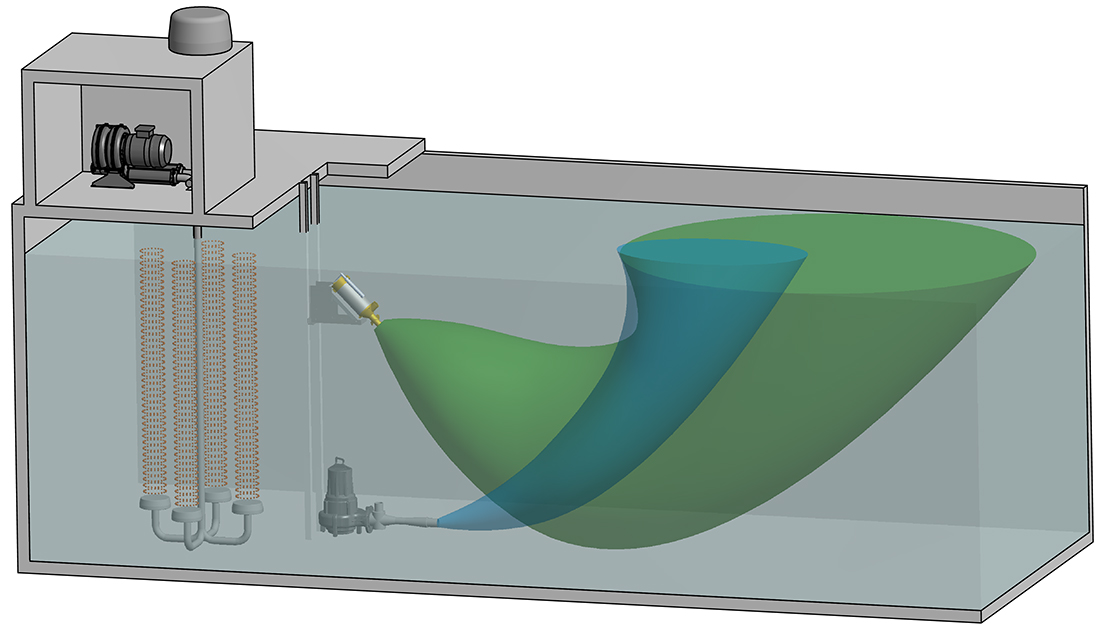

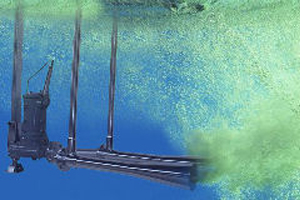

| BUBBLE SIZE | The high rotation speed of the propeller generates a large amount of MICRO-BUBBLES having a diameter less than 1 mm. As a result, a very large air-water exchange surface is created.

| Medium or large-diameter bubbles can be generated depending on the type of diffuser. Smaller bubbles can be generated provided that the blower’s power is significantly increased. The plates with micro-holes can get easily clogged.

| Medium-large diameter bubbles. Since air comes into contact with water inside an ejection tube, the bubble diameter is only reduced by the turbulence of the flow.

|

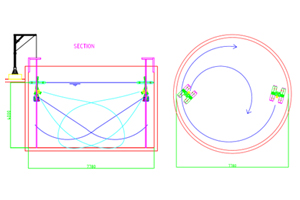

| MIXING | Great capacity of mixing and homogenization.

Bubbles follow the flow generated by the impeller and afterwards rise vertically to the surface.

The spreading of the bubbles all over a large surface prevents them from aggregating, that would lead to a lower dissolution efficiency.

Its circulation capacity makes the entire volume’s treatment easier, avoiding the settling of solids and the appearance of dead zones with a low oxygen concentration.

| Low mixing and homogenization capacity.

Bubbles rise to surface following a vertical trajectory, causing a shorter contact time with water.

While rising, bubbles aggregate, increasing their average diameter and reducing the air-water contact surface. As a result, the dissolution efficiency drops.

| Low mixing capacity.

Starting from the bottom, bubbles rise to the surface with a strongly vertical trajectory. The mixing effect is very moderate and it is generated by the water flow of the pump, which is determined by its specific flow rate.

|

| AIR TEMPERATURE | It injects air taken directly from outside without changing its temperature. | The blower and the air distribution tubes heat up during operation, increasing the temperature of the injected air. Consequently, injected air will contain a lower percentage of oxygen.

| It injects air taken directly from outside without changing its temperature. |

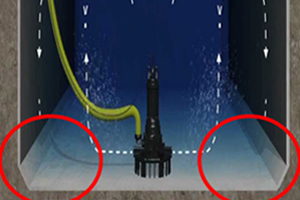

| INSTALLATION | Low installation costs.

Easy system with self-standing components. No additional spaces are required. It can be installed on floating supports for test purposes without stopping the system.

| High installation costs.

Complex system: valves, downpipes, pipes, diffusers.

A dedicated, soundproof and air-conditioned technical room is needed for the blower.

| Low installation costs.

Easy system with self-standing components.

No additional spaces are required.

It cannot be installed for test purposes, because it needs to be installed on the bottom and motors are usually heavy and cumbersome.

|

| VERSATILITY | It can be adjusted to meet any requirements.

It can target the micro-bubbles flow towards multiple directions.

Easy to be installed through rails or floating supports for large-sized lagooning systems.

It can be easily upgraded with new components if necessary.

Dedicated supports for specific requirements can be developed. | Static system.

Increasing its capacity may require complex operations and sometimes this could not be feasible at all.

Not suitable for lagooning systems. | It can target the micro-bubbles flow towards multiple directions.

It can be easily upgraded with new components if necessary.

Not suitable for lagooning systems. |

| MAINTENANCE | Self-standing components.

It does not require the system to be emptied or stopped and it can be handled from the surface or through inspection.

Easy and quick handling that can be carried out by just one operator. All motors can be fully reconditioned through agreed maintenance programmes.

| Single system

The water treatment system has to be stopped and the compartment needs to be emptied and sanitised before having access to diffusers.

Complex maintenance due to the high number of elements to be installed, which are also difficult to be reached for checking purposes.

| Self-standing components.

It does not require the system to be emptied or stopped and it can be handled from the surface or through inspection.

Easy and quick handling that can be carried out by just one operator only for the smallest models.

|

| NOISE AND HEATING | The submersible motor does not heat up and it is very smooth-running.

| The external blower generates noise and can reach high temperatures.

| The submersible motor does not heat up and it is very smooth-running.

|

| OPERATION IN WATERS CONTAINING SOLIDS OR SLUDGES | Suitable to operate in liquids with a high concentration of solids or sludges.

Operation in the upper part of the treatment tanks allows the aerator to be always activated in clean waters with a low solid content, preventing any clogging. | Diffusers can be used in waters with a high content of sludges and solids if the oxidation process is not stopped for long periods of time. In fact, if the oxidation process stops, diffusers are likely to be clogged by the settled sludges and later on they could be broken by the operating pressure. | Activation problems may occur after prolonged downtimes.

Since the pump is placed on the bottom of the tank, its motor and injection pipes become covered with solids and sludge during stoppages or downtime.

The Venturi system works thanks to a delivery pipe with a reduced diameter. It means that this upgrade could cause clogging issues when solids or sludge are present. |

| ENERGY CONSUMPTION / EFFICIENCY | Higher energy efficiency.

Since the aerator is installed a few centimetres away from the surface, the pressure that needs to be overcome to inject air is really low.

The bubbles trajectory is the longest possible. Starting from the surface, they reach the bottom and spread all over a large area, then they slowly rise towards the atmosphere. | The deeper the tank, more power will be needed to allow the blower to suck in air from the surface. Injection is performed on the bottom and without using mixers. This causes a quick rise of the bubbles towards the surface. | The deeper the tank, more power will be needed to allow the pump to suck in air from the surface. Injection is performed on the bottom and without using mixers. This causes a quick rise of the bubbles towards the surface. |